Every time we communicate with customers, one word is mentioned repeatedly: warranty. Each customer wants a different warranty period, ranging from two years to three years, and some want five years.

But in fact, in many cases, customers themselves may not know where this warranty time is derived, or they just follow the crowd and think that LEDs should be guaranteed for such a long time.

Today, I will take you into the world of LED to find out how the life of lamps is defined and judged.

First of all, when it comes to LEDs, in terms of appearance, we can tell at a glance that they are different from traditional light sources, because almost all LEDs have a distinctive feature - a heat sink.

Various heat sinks are not for the beauty of LED lamps, but to make the LEDs work better.

Then customers will wonder why previous light sources rarely used radiators, but in the LED era almost all lamps use radiators?

Because previous light sources relied on thermal radiation to emit light, such as tungsten filament lamps, which rely on heat to emit light, so they are not afraid of heat. The basic structure of LED is a semiconductor P-N junction. If the temperature is slightly higher, the working performance will decrease, so heat dissipation is very important for LED.

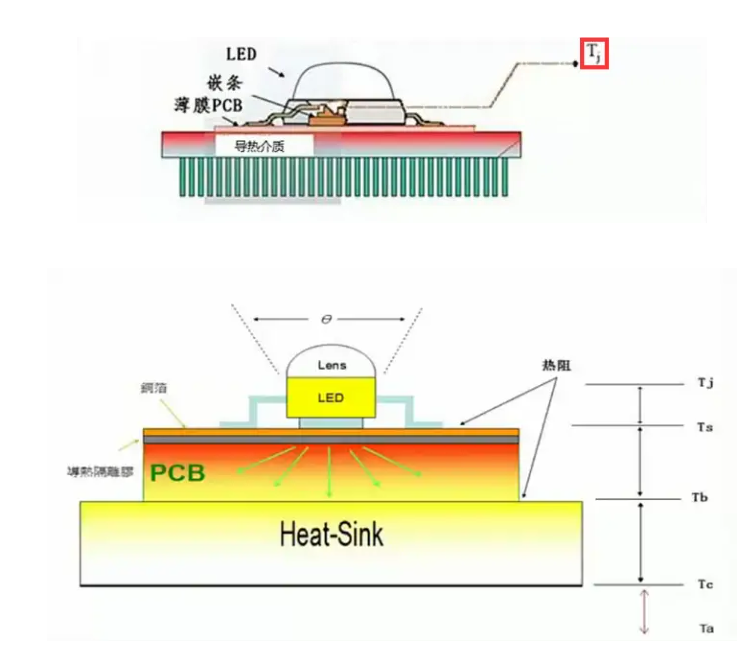

First, let us take a look at the composition and schematic diagram of LED

Tips : The LED chip will generate heat when working. We refer to the temperature of its internal PN junction as junction temperature (Tj).

And, most importantly, the life of LED lamps is closely related to the junction temperature.

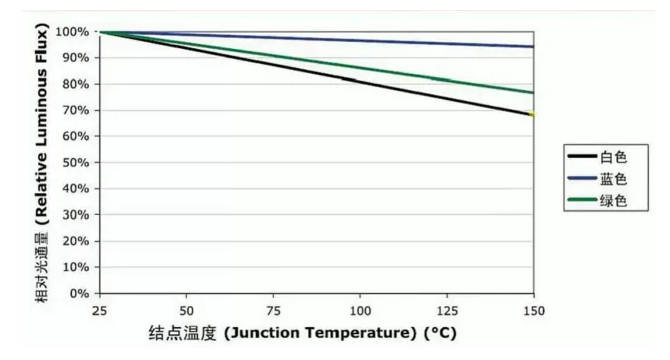

A concept we need to understand: When we talk about the life of an LED, it does not mean that it is completely unusable, but when the LED light output reaches 70%, we generally think that ‘its life has ended’.

As can be seen from the above figure, if the junction temperature is controlled at 105°C, then the luminous flux of the LED lamp will attenuate to 70% when the LED lamp is used for about 10,000 hours; and if the junction temperature is controlled at about 60°C, then its working time will be about 100,000 hours + hour, the luminous flux will decrease to 70%. The life of the lamp is increased by 10 times.

In daily life, what we most often encounter is that the LED life span is 50,000 hours, which is actually a data when the junction temperature is controlled at 85°C.

Since the junction temperature plays such an important role in the life of LED lamps, how to reduce the junction temperature? Don't worry, let's first take a look at how the lamp dissipates heat. After understanding the heat dissipation method, you will naturally know how to reduce the junction temperature.

How lamps dissipate heat?

First, you need to know the three basic ways of heat transfer: conduction, convection, and radiation.

The main transmission paths of the radiator are conduction and convection heat dissipation, and radiation heat dissipation under natural convection.

Basic principles of heat transfer:

Conduction: The way heat travels along an object from a warmer part to a cooler part.

What are the factors that affect heat conduction?

① Thermal conductivity of heat dissipation materials

② Thermal resistance caused by heat dissipation structure

③ Shape and size of thermally conductive material

Radiation: The phenomenon of high-temperature objects radiating heat directly outwards.

What are the factors that affect thermal radiation?

① Thermal resistance of the surrounding environment and medium (mainly considering air)

② The characteristics of the thermal radiation material itself (generally dark colors radiate more forcefully, but in fact the radiation transfer is not particularly important, because the temperature of the lamp is not too high and the radiation is not very strong)

Convection: A method of transferring heat by the flow of gas or liquid.

What are the factors that affect thermal convection?

① Gas flow and speed

② Specific heat capacity, flow speed and volume of liquid

In LED lamps, the heat sink accounts for a large part of the cost of the lamp. Therefore, in terms of the structure of the radiator, if the materials and design are not good enough, then the lamp will have many after-sales problems.

However, in fact, these are just the foreshadowing, and now is the focus.

As a consumer, how do you judge whether the heat dissipation of a lamp is good or not?

The most professional method is of course to use professional equipment to conduct junction temperature testing.

However, such professional equipment may be prohibitive for ordinary people, so all we have left is to use the most traditional method of touching the lamp to sense the temperature.

Then a new question arises. Is it better to feel hot or not?

If the radiator is hot when you touch it, it's definitely not good.

If the radiator is hot to touch, the cooling system must be bad. Either the radiator has insufficient heat dissipation capacity and the chip heat cannot be dissipated in time; or the effective heat dissipation area is not enough, and there are deficiencies in the structural design.

Even if the lamp body is not hot to touch, it is not necessarily good.

When the LED lamp is working properly, a good radiator must have a lower temperature, but a cooler radiator is not necessarily a good one.

The chip does not generate much heat, conducts well, dissipates enough heat, and does not feel too hot in the hand. This is a good cooling system, the only "disadvantage" is that it's a bit of a waste of material.

If there are impurities under the substrate and there is no good contact with the heat sink, the heat will not be transferred out and will accumulate on the chip. It's not hot to the touch outside, but the chip inside is already very hot.

Here, I would like to recommend a useful method - the "half-hour illumination method" to determine whether the heat dissipation is good.

Note: "Half-hour illumination method" comes from the article

Half hour illumination method: As we said before, generally as the LED junction temperature increases, the luminous flux will decrease. Then, as long as we measure the change in illumination of the lamp shining at the same position, we can infer the change in junction temperature.

First, choose a place that is not disturbed by external light and light the lamp.

After lighting up, immediately take a light meter and measure it, for example 1000 lx.

Keep the position of the lamp and the illuminance meter unchanged. After half an hour, use the illuminance meter to measure again. 500 lx means that the luminous flux has dropped by 50%. It is extremely hot inside. If you touch the outside, it is still fine. It means that the heat has not come out. Difference.

If the measured value is 900 lx and the illumination only drops by 10%, it means it is a normal data and the heat dissipation is very good.

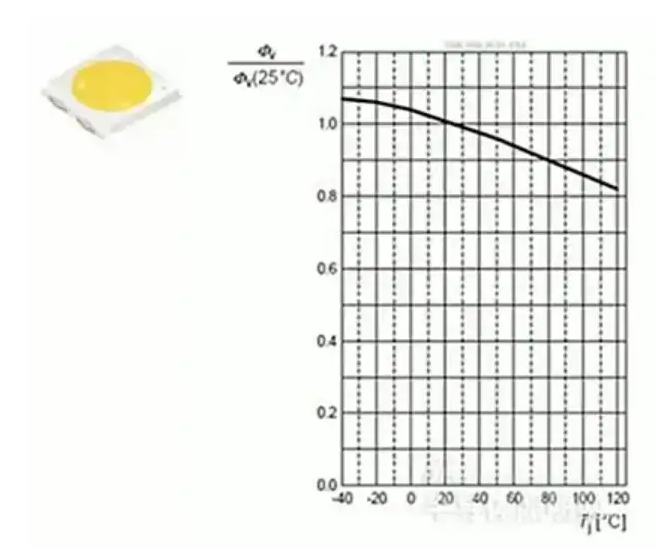

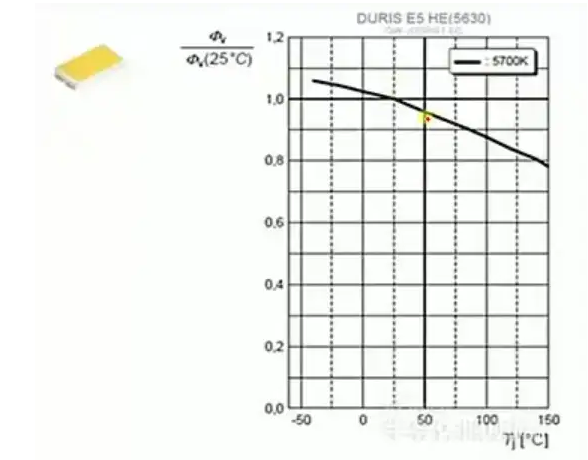

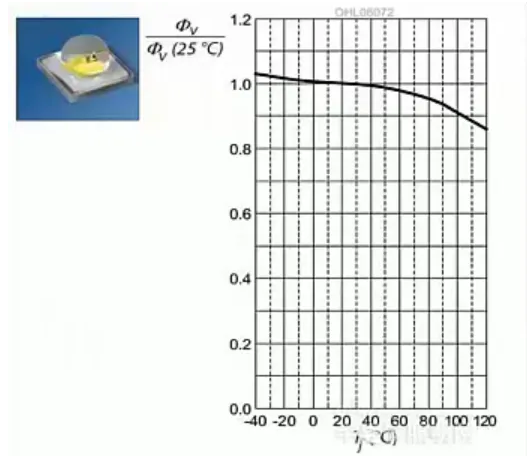

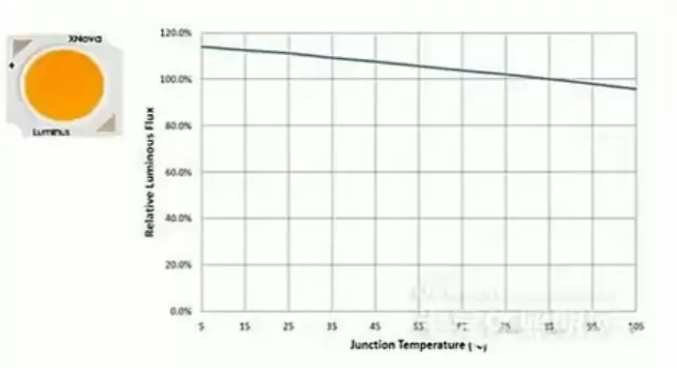

The scope of application of the "half-hour illumination method": We enumerate the "luminous flux VS junction temperature" change curve of several commonly used chips. From this curve, we can see how many lumens the luminous flux has dropped, and we can indirectly know how many degrees Celsius the junction temperature has risen to.

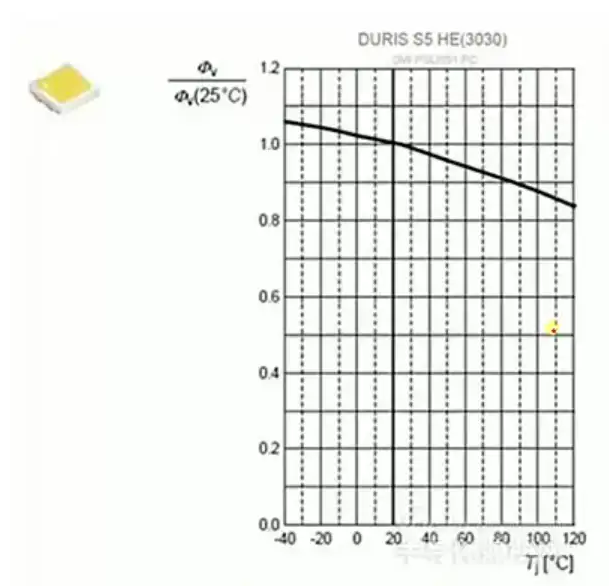

Column one:

For the OSRAM S5 (30 30) chip, the luminous flux dropped by 20% compared to 25°C, and the junction temperature has exceeded 120°C.

Column two:

For the OSRAM S8 (50 50) chip, the luminous flux dropped by 20% compared to 25°C, and the junction temperature has exceeded 120°C.

Column three:

For the OSRAM E5 (56 30) chip, the luminous flux dropped by 20% compared to 25°C, and the junction temperature has exceeded 140°C.

Column four:

For the OSLOM SSL 90 white chip, the luminous flux is 15% lower than that at 25°C, and the junction temperature has exceeded 120°C.

Column five:

Luminus Sensus Serise chip, the luminous flux dropped by 15% compared with 25℃, and the junction temperature has exceeded 105℃.

As can be seen from the above pictures, if the illumination in the hot state drops by 20% after half an hour compared to the cold state, the junction temperature has basically exceeded the tolerance range of the chip. It can basically be judged that the cooling system is unqualified.

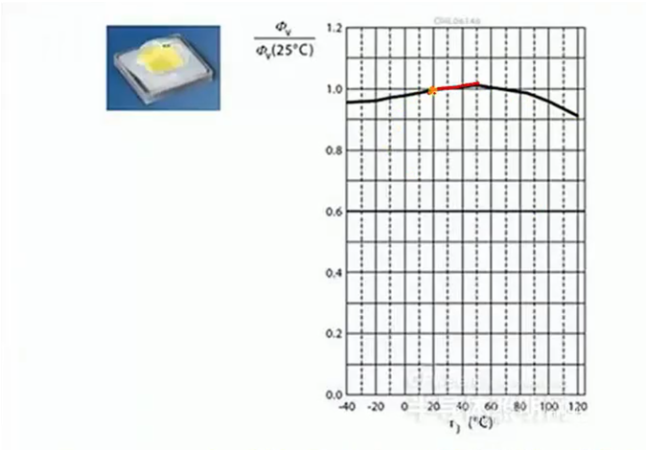

Of course, this is the majority of cases, and everything has exceptions, as shown in the figure:

Of course, for most LEDs, we can use the half-hour illumination method to judge whether it is good or not within a 20% drop.

Have you learned? When you choose lamps in the future, you must pay attention. You can't just look at the appearance of the lamps, but use your sharp eyes to select the lamps.

Post time: May-24-2024